Scroll down

Having our own production facilities allows us to have flexible and fast production processes, that are of high quality.

Our production facilities are in a continuous state of development and investment, proving our commitment to innovate our own production, while still focusing on sustainability. With new and improved machines at Pacapime Hungary and Belgium and at Dutch-Bangla Pack Limited, the official opening of LC Shankar’s new production facility, as well as upgrades at our Big Bags reconditioning service WorldBag, we try to improve every day.

Official opening LC Shankar production facility

LC Shankar’s new production facility opened its doors in 2022, in Pietermaritzburg, South Africa. This custom-built production and distribution centre doubles its previous size to an impressive 10,000 m2. We celebrated this long-term strategy for expansion, heightened productivity, and reverse integration with an official opening in 2023, in the presence of Lucas Lammers.

WorldBag: new machines and new FIBC cleaning methods

Progress at WorldBag: we have installed a new big bag cleaning machine for even better cleaning results. Thanks to this machine, more product residue can be removed from the bag. The WorldBag air cleaning facility also received an upgrade, for example by installing LED lighting. In addition, WorldBag now offers the possibility for wet cleaning of used big bags. Watch the video to learn more.

Production upgrades at Dutch-Bangla Pack Limited

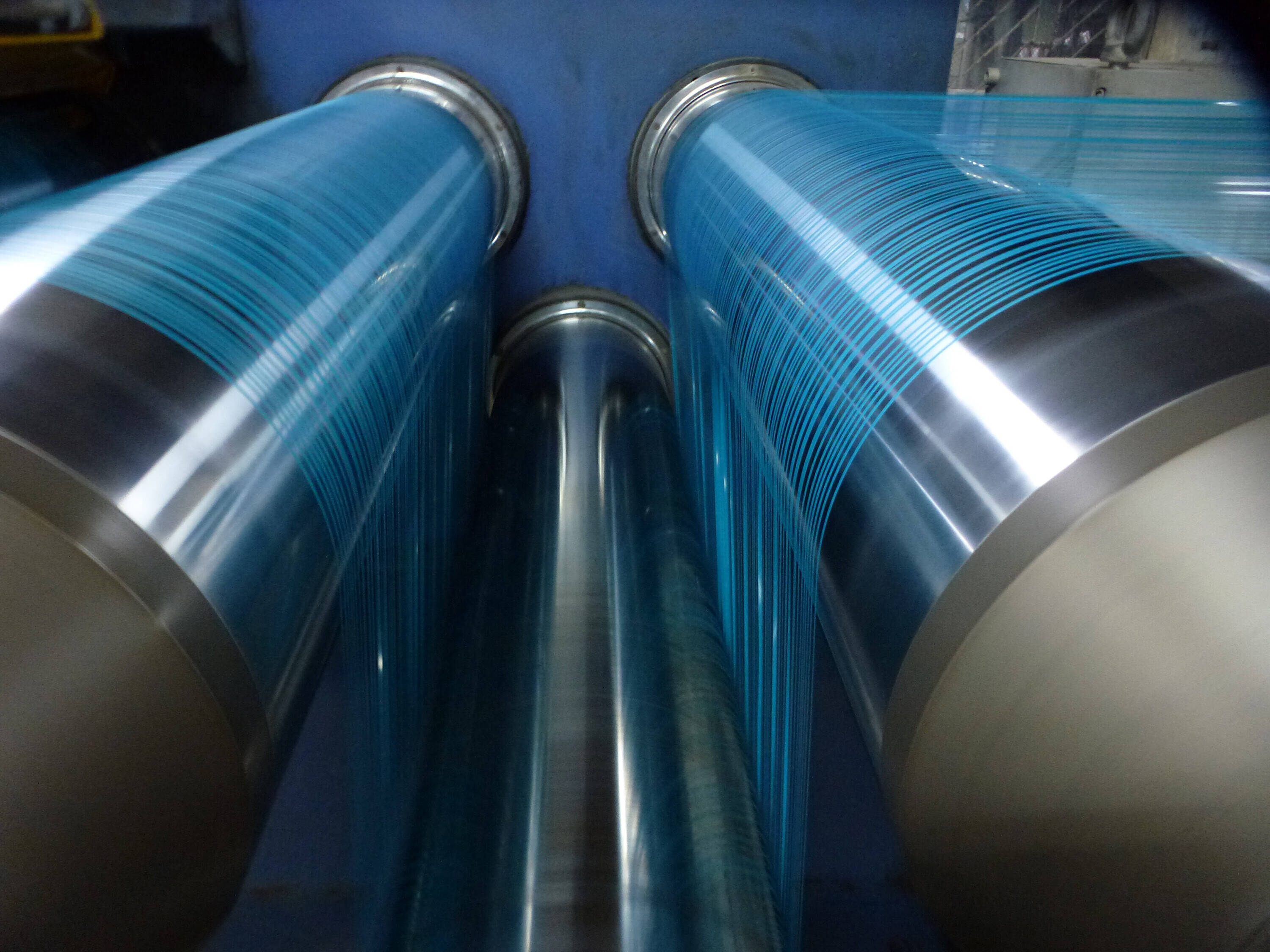

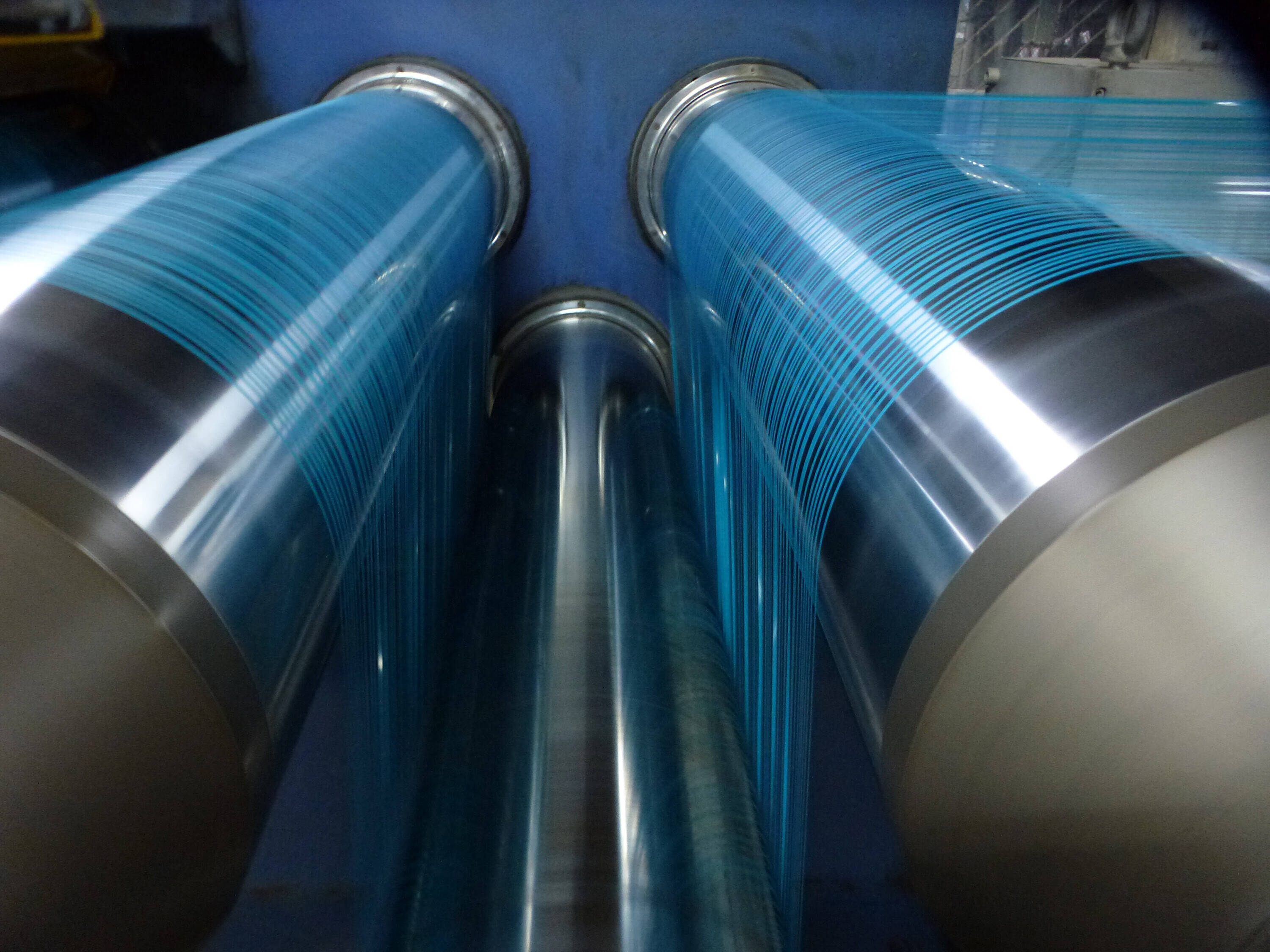

Dutch-Bangla Pack Limited (DBPL) recently installed a Polypropylene Multifilament Extruder. With this machine, DBPL can now fabricate PPMF loops and PP sewing yarn, presenting a viable alternative to polyester. This installation marks a significant stride towards efficiency and sustainability in DBPL's manufacturing processes.

DBPL has also installed new ultrasonic hemming machines that can be used to ultrasonically hem the inner liner and the fabric spout, and the vertical seam of the emptying spout. This can replace the current hemming with yarn, minimising the contamination risk.

Developments in cardboard production

Pacapime Belgium experienced a significant growth, producing 86 million m² of corrugated cardboard. A 4.9% increase from 2022, thanks to a new night shift. With a 19% reduction in energy consumption per unit over two years and a notable 27% decrease in CO2 emissions per unit, Pacapime Belgium demonstrates their dedication to environmental responsibility.

And in addition, Saica's minority stake acquisition emphasises a commitment to securing paper supply and leveraging industry expertise, aligning with the mutual sustainability goals.

Pacapime Hungary produces 60 million m2 of corrugated board annually. Equipped with newly purchased cutting-edge machinery that proces up to 12,000 pieces per hour or have a capacity of 15,000 pieces trays per hour, these machines ensure efficiency. Additionally, two other machine, one 4 colour and one 6+ colour with varnish, enhance production capabilities even further, with outputs of 28,000 pieces trays per hour.

Annual Report 2023

Always near

GRI 102-10

Own Production

Always near

Production upgrades at Dutch-Bangla Pack Limited

Dutch-Bangla Pack Limited (DBPL) recently installed a Polypropylene Multifilament Extruder. With this machine, DBPL can now fabricate PPMF loops and PP sewing yarn, presenting a viable alternative to polyester. This installation marks a significant stride towards efficiency and sustainability in DBPL's manufacturing processes.

DBPL has also installed new ultrasonic hemming machines that can be used to ultrasonically hem the inner liner and the fabric spout, and the vertical seam of the emptying spout. This can replace the current hemming with yarn, minimising the contamination risk.

WorldBag: new machines and new FIBC cleaning methods

Progress at WorldBag: we have installed a new big bag cleaning machine for even better cleaning results. Thanks to this machine, more product residue can be removed from the bag. The WorldBag air cleaning facility also received an upgrade, for example by installing LED lighting. In addition, WorldBag now offers the possibility for wet cleaning of used big bags. Watch the video to learn more.

Official opening LC Shankar production facility

LC Shankar’s new production facility opened its doors in 2022, in Pietermaritzburg, South Africa. This custom-built production and distribution centre doubles its previous size to an impressive 10,000 m2. We celebrated this long-term strategy for expansion, heightened productivity, and reverse integration with an official opening in 2023, in the presence of Lucas Lammers.

Developments in cardboard production

Pacapime Belgium experienced a significant growth, producing 86 million m² of corrugated cardboard. A 4.9% increase from 2022, thanks to a new night shift. With a 19% reduction in energy consumption per unit over two years and a notable 27% decrease in CO2 emissions per unit, Pacapime Belgium demonstrates their dedication to environmental responsibility.

And in addition, Saica's minority stake acquisition emphasises a commitment to securing paper supply and leveraging industry expertise, aligning with the mutual sustainability goals.

Pacapime Hungary produces 60 million m2 of corrugated board annually. Equipped with newly purchased cutting-edge machinery that proces up to 12,000 pieces per hour or have a capacity of 15,000 pieces trays per hour, these machines ensure efficiency. Additionally, two other machine, one 4 colour and one 6+ colour with varnish, enhance production capabilities even further, with outputs of 28,000 pieces trays per hour.

Having our own production facilities allows us to have flexible and fast production processes, that are of high quality.

Our production facilities are in a continuous state of development and investment, proving our commitment to innovate our own production, while still focusing on sustainability. With new and improved machines at Pacapime Hungary and Belgium and at Dutch-Bangla Pack Limited, the official opening of LC Shankar’s new production facility, as well as upgrades at our Big Bags reconditioning service WorldBag, we try to improve every day.

Own Production

GRI 102-10

Annual Report 2023